Diecasting in Malaysia has grown into an essential industry, supporting different industries such as telecoms, automotive, electronics and manufacturing of consumer goods. It is one of the most important metal-forming procedures Diecasting involves the injection of hot metal into molds under pressure that creates high-quality components with precise details. Diecasting in Malaysia is a highly efficient process. Malaysian diecasting sector benefits from its location in a strategic area with a skilled workforce and modern manufacturing capabilities. This has made Malaysia an essential actor in the international market for diecasting as the market has grown gradually over time in order to satisfy the growing demands for premium metal components.

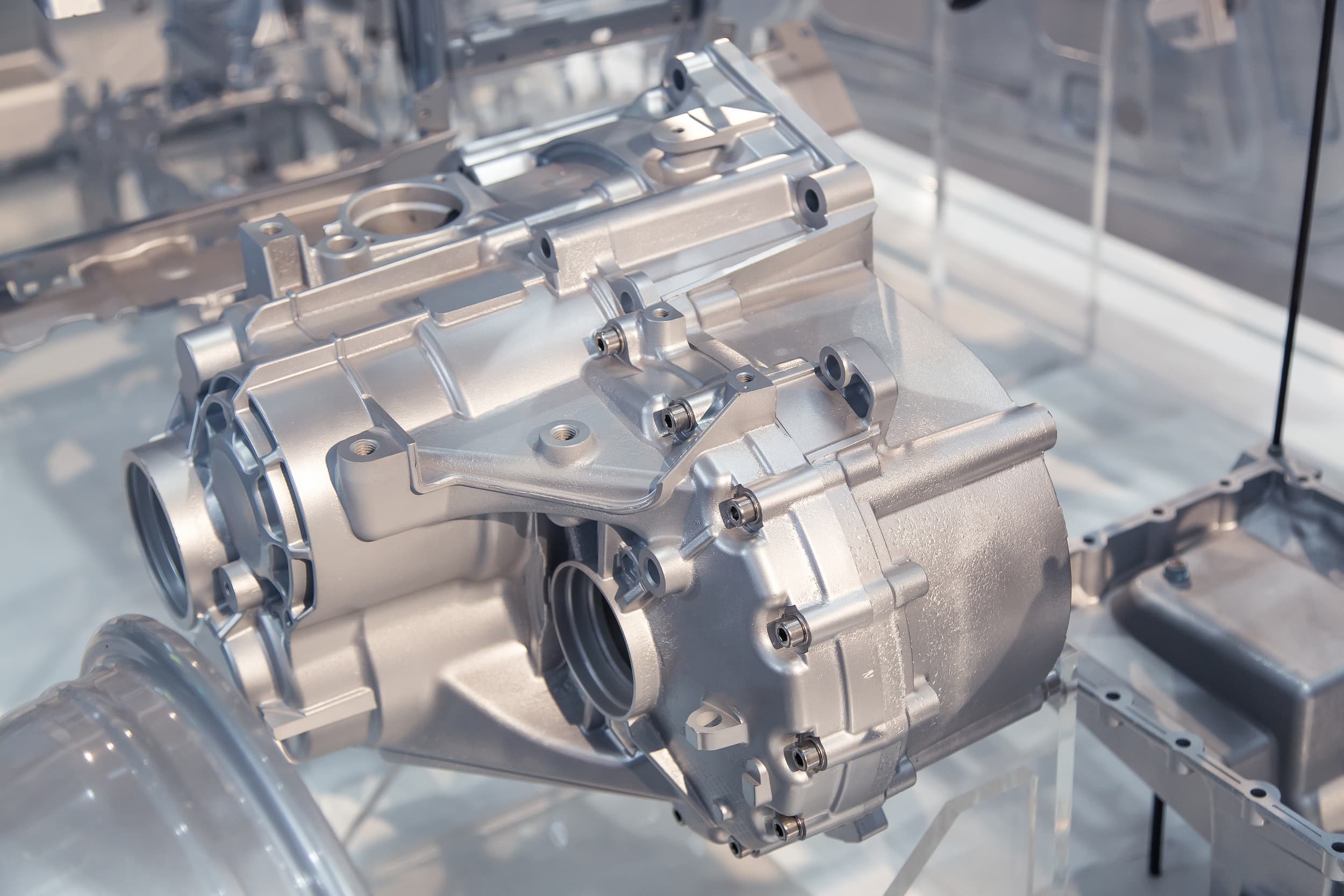

One of the primary drivers of the expansion of diecasting of Malaysia is Malaysia’s expanding automobile industry. Automobile manufacturers depend heavily on diecast elements for engine or transmissions as well as various mechanical components because of its ability to make extremely lightweight, strong and intricate shapes. Malaysian diecasting firms have proven themselves as reliable sources of parts for automobiles, both for car manufactures in the country as well as for multinational manufacturers. Its dedication to high-quality and precise diecasting has enabled it to gain a competitive advantage in this area, and contribute significantly to the supply chain throughout Southeast Asia and beyond.

In addition to the auto sector, Malaysia’s electronics and telecoms industries also are a major factor in the market for diecast items. As technology advances, industries, the requirement for precision and intricate parts has never been more pressing. Diecasting is particularly suited for making electronic components that include connectors, casings as well as heat sinks that are crucial for efficient operation. Malaysian diecasting firms have gained proficiency in the production of tiny, light components which meet the strict requirements of these fields. Technology continues to improve and advance, diecasting is essential to creating high-performance parts to make modern electronic devices as well as communications infrastructure.

A further advantage that precision die casting Malaysia is the cost effectiveness. Diecasting is renowned to produce large quantities of products quickly and efficiently and efficiently, which is a perfect choice for companies that need large-scale production. Malaysia’s low labor cost and access to raw materials increase the efficiency of the process, which allows companies that diecast the products they manufacture at an affordable price. The combination of precision, speed, and value is what makes Malaysian diecasting businesses popular with businesses around the globe who are looking for trustworthy companies that can deliver quality parts in huge quantity. Diecasting’s advantages in terms of economics in Malaysia allows the industry to be resilient despite worldwide market volatility.

The environmental sustainability of diecasting as a process for manufacturing is a crucial aspect to consider in light of the fact that many industries worldwide have a strong focus on eco-friendly processes. Diecasting in Malaysia is making strides towards adopting environmentally sustainable methods, like recycling scrap metal, and optimizing the use of energy during manufacturing. Reusing diecasting molds to run long production runs also reduces waste and the industry is now in sync with international efforts to minimize the impact on the environment. As the focus shifts to sustainable practices across the entire industry, Malaysian diecasting companies are more and more focused on improving the efficiency of their operations to reduce their carbon footprint, while ensuring top standard of production.

Looking to the future, the diecasting industry in Malaysia is poised for continued growth as the demand for precision-manufactured components rises. Malaysia’s capacity to blend the latest technology with an experienced workforce has made it an important actor in the worldwide diecasting industry. Incorporating new technology including robotics, automation as well as artificial intelligence into the process of diecasting is likely to enhance efficiency and quality more. With a solid basis established that is firmly established, the Malaysian diecasting industry has the capacity to be able to adjust to needs of the market and provide top-quality products for a broad spectrum of different industries.