Diecasting in Malaysia: Precision Engineering and Industrial Growth

Diecasting has become an integral part in Malaysia’s manufacturing industry and plays a vital function in the manufacturing of precision metal parts. Diecasting, which involves introducing molten metal in the mold at the pressure of a high, is known because of its capability to create complicated shapes, with precise tolerances as well as smooth surfaces. In the past, Malaysia has become a major player in the international diecasting market, due to the advancements in technology, highly skilled workers, as well as its strategic industrial strategies. This article focuses on the growth, present state as well as the future of the industry for diecasting in Malaysia.

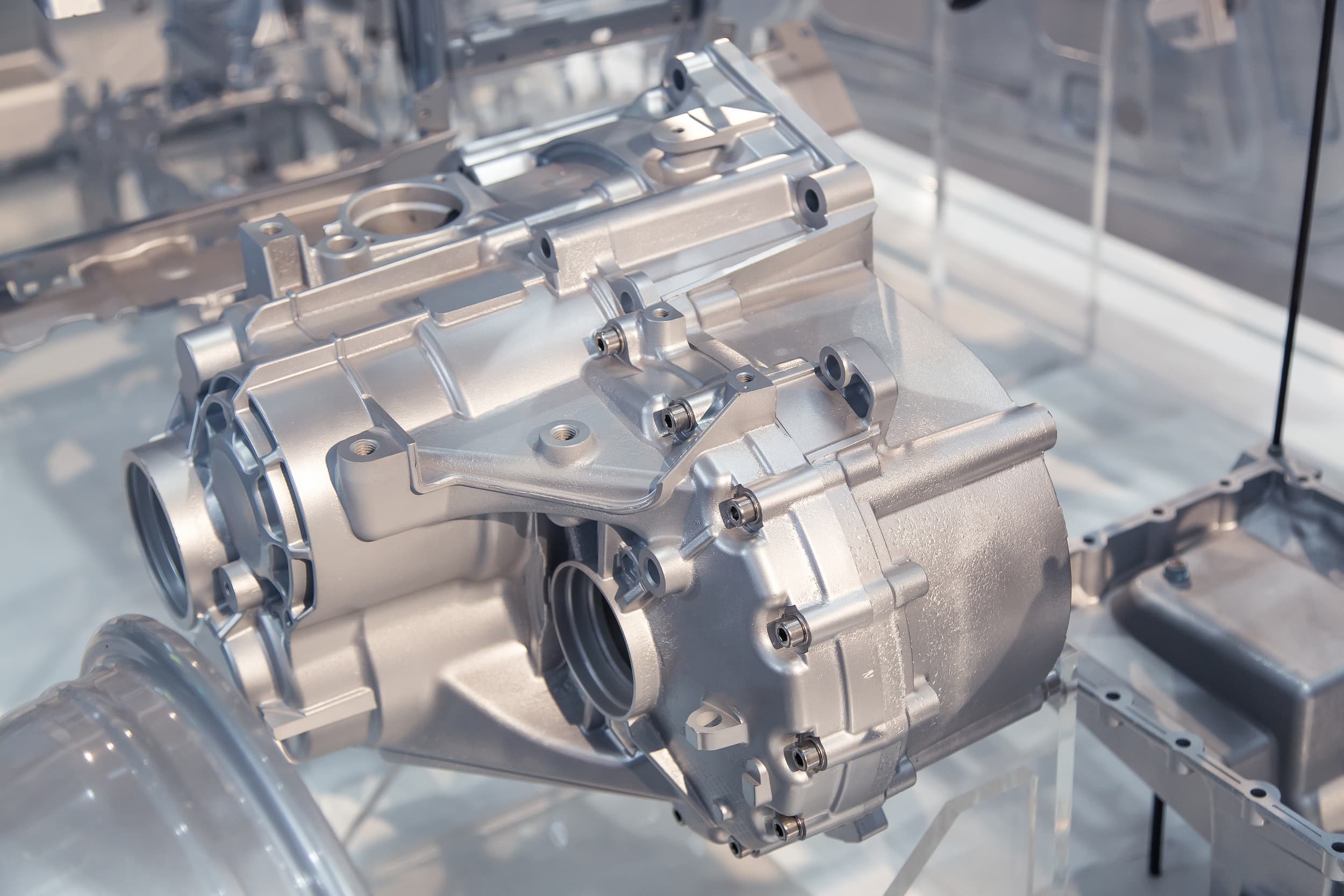

Diecasting’s origins and diecasting in Malaysia are traced to the 20th century’s midpoint, which is in the time when Malaysia was beginning its industrialization journey. At first, the business was was primarily focused on small-scale, low-volume manufacturing for domestic use. But as the economy of Malaysia increased and diversified and diversified, so did its capabilities in manufacturing. Nowadays, Malaysian diecasting companies produce various items ranging from automotive parts, electronics housings and even complicated components for consumer goods. This expansion has been brought about by substantial investments in cutting-edge machines and cutting-edge manufacturing techniques that have established Malaysia as an important hub for premium diecast items.

Technology-driven innovation is driving Malaysia’s growth in the diecasting industry. Diecasting equipment that is modern and equipped with sophisticated control systems guarantee high-quality and efficient manufacturing. Techniques like computer-aided designing (CAD) or computer-aided manufacture (CAM) revolutionized manufacturing, and enabled the production of extremely detailed and precise components. The advancements in technology reduce waste materials and speed up production which makes Malaysian companies that diecast are better positioned on the global scene. This shift in the industry to use high-quality and lightweight materials like aluminum and magnesium alloys have increased the performance and quality of the diecasting products that meet the strict requirements of international market.

The highly skilled workforce of Malaysia is an additional element that has contributed to the growth of the diecasting industry. Malaysian workers are well-known for their technical knowledge as well as their commitment to sustaining high standards for high-quality. The educational institutions and the specific training programs have been essential in creating an array of talents which is able to meet the changing industry demands. Professional development continues to ensure that employees are proficient making use of the most recent technologies and methods. A focus on enhancing their skills is allowing Malaysian diecasters to create parts that are in line with international standards. This has helped to strengthen Malaysia’s standing as a reliable source of precisely engineered components.

If we look to the future, the possibilities for the industry of Nickel chrome plating Malaysia are promising. Global demand for diecast products is growing due to the growth of industries like electronic, aerospace, automotive and consumer products. The strategic location of Malaysia along with its resilient infrastructure and a favorable environment for business is a desirable investment destination for those looking to invest in the industry of diecasting. In addition, there is an increased focus on sustainability in the business. Malaysian diecasters are now employing environmentally friendly practices like recycling of materials and adopting energy-efficient manufacturing processes. They are not only reducing their environmental footprint, but they also go along with international trends toward sustainability in manufacturing.

Diecasting is a major industry in Malaysia has grown from humble beginnings into a major participant in the global industrial scene. The advancements in technology, the highly competent workforce, as well as supportive policy-making by the government all contribute to the growth. Since the demand for precision metal parts continues to grow, Malaysia is well-positioned to benefit from the opportunities. Through embracing sustainability and innovation in its approach, the Malaysian diecasting sector can keep its position as a leader and keep driving the economy. Diecasting’s future in Malaysia appears promising, and has the potential to expand further as well as success on the global market.